IHC hydraulic hammer

Usage Environment

The all-purpose IHC hydraulic hammer can be used in any environment.

IHC hydraulic hammers can be used anywhere in the air or underwater for land and offshore construction.

More than 30 years of experience in development, production and use have been put to use in this innovative device.

Maximum hydraulic hammer S-2300 and minimum hydraulic hammer S-35

Steel pipe pile driving using S-500 (φ3500mm, τ44mm, l=24.5m)

- Continuous operation and impact energy display

- Blow energy is transmitted to the display panel for each blow, and can be continuously adjusted in the range of approximately 3% to 100%.

- Integrated structure, high operability

- It is composed of only a few parts, and there are no bolts or hoses inside the hammer. Critical parts such as valves and sensors are mounted in locations where they can be easily replaced from the outside. This helps increase the reliability of the hammer.

- Underwater pouring control device

- A sensor is installed that can control pile driving operations even underwater.

- Thorough examination

- Thoroughly tested using a variety of piles, the hammer has proven to be reliable and easy to operate on land and at sea.

- Features and performance

- Higher number of strikes (40-120 times/min) and higher efficiency increase productivity.

- Easy to operate.

- Automatic printing of stakeout information.

- Accurate pile driving is possible by displaying the energy per blow.

- Piles can be driven at any angle (theoretically horizontal).

- Low wear due to ram support by lubricated bearings.

- Can be pulled out. (For small hydraulic hammers.)

- No need for a cushion due to the development of a special anvil. (For steel pipe piles.)

- Delivers maximum impact energy even when working in deep water.

- Equipped with a special pile guide sleeve, it is possible to freely drive steel pipe piles and sheet piles.

- Worldwide services and assistance

- IHC Hydraulic Hammer Company provides services worldwide and also assists in pile driving analysis, hammer selection and operation.

Optimal Performance

Optimal performance for versatile living environments.

IHC Hydraulic Hammer Co., Ltd. has developed two types of hydraulic hammers with outstanding performance, versatility, and reliability.

Concrete pile driving with SC-200

- S series

- S series hydraulic hammer is mainly designed for steel pipe pile driving and underwater driving. The maximum impact speed of the ram is approximately 6.5 m/s, which corresponds to a fall height of 2 m. Adjust the stroke when driving concrete piles.

- SC series

- SC series hydraulic hammers are designed specifically for concrete pile driving. Also applicable to steel pipe piles. The maximum striking speed of the ram is slower due to the heavier ram weight. (approx. 5.5 m/sec) The outer diameter is larger than the S series, but the length is shorter.

- Expert assistance experience

- At IHC Hydraulic Hammer, our experts will select the most suitable hammer based on our experience around the world.

Hammer type S type (S-30 to S-200)

Activation

| S-30 | S-35 | S-70 | S-90 | S-120 | S-150 | S-200 | |

|---|---|---|---|---|---|---|---|

| Maximum impact energy (kNm) | 30 | 35 | 70 | 90 | 120 | 150 | 200 |

| Minimum impact energy (kNm) | 2 | 2 | 2 | 2 | 6 | 6 | 10 |

Number of blows at maximum blow energy (times/min) |

65 | 60 | 50 | 50 | 44 | 44 | 45 |

Mass

| S-30 | S-35 | S-70 | S-90 | S-120 | S-150 | S-200 | |

|---|---|---|---|---|---|---|---|

| Rum (ton) | 1.5 | 3 | 3.5 | 4.5 | 6.2 | 7.5 | 10.0 |

| Body (including ram) (ton) | 3.7 | 7.1 | 8.3 | 9.6 | 14.3 | 16.2 | 24.5 |

Dimensions

| S-30 | S-35 | S-70 | S-90 | S-120 | S-150 | S-200 | |

|---|---|---|---|---|---|---|---|

| Outer diameter (mm) | 457 | 610 | 610 | 610 | 712 | 712 | 915 |

| Length (mm) | 5745 | 5600 | 7130 | 7880 | 7960 | 8710 | 8920 |

Hydraulic data

| S-30 | S-35 | S-70 | S-90 | S-120 | S-150 | S-200 | |

|---|---|---|---|---|---|---|---|

| Working pressure (bar) | 280 | 220 | 230 | 280 | 250 | 280 | 250 |

| Hydraulic oil flow rate (l/min) | 160 | 160 | 220 | 220 | 460 | 460 | 750 |

| Motor (kW) | 130 | 130 | 167 | 167 | 344 | 344 | 435 |

| Hydraulic hose (inner diameter) (mm) | 25 | 32 | 32 | 32 | 38 | 38 | 50 |

Hammer type S type (S-280 to S-2300)

Activation

| S-280 | S-500 | S-600 | S-900 | S-1200 | S-1800 | S-2300 | |

|---|---|---|---|---|---|---|---|

| Maximum impact energy (kNm) | 280 | 500 | 600 | 900 | 1200 | 1800 | 2300 |

| Minimum impact energy (kNm) | 10 | 20 | 20 | 45 | 60 | 180 | 230 |

Number of blows at maximum blow energy (times/min) |

45 | 45 | 36 | 30 | 30 | 30 | 30 |

Mass

| S-280 | S-500 | S-600 | S-900 | S-1200 | S-1800 | S-2300 | |

|---|---|---|---|---|---|---|---|

| Rum (ton) | 13.6 | 25.0 | 30 | 45 | 60.0 | 75.0 | 115 |

| Body (including ram) (ton) | 29.0 | 55.0 | 63 | 125 | 138.0 | 200.0 | 260.0 |

Dimensions

| S-280 | S-500 | S-600 | S-900 | S-1200 | S-1800 | S-2300 | |

|---|---|---|---|---|---|---|---|

| Outer diameter (mm) | 915 | 1220 | 1220 | 1625 | 1625 | 1830 | 1830 |

| Length (mm) | 10190 | 10200 | 11000 | 12785 | 14065 | 15840 | 18040 |

Hydraulic data

| S-280 | S-500 | S-600 | S-900 | S-1200 | S-1800 | S-2300 | |

|---|---|---|---|---|---|---|---|

| Working pressure (bar) | 300 | 300 | 280 | 250 | 310 | 230 | 300 |

| Hydraulic oil flow rate (l/min) | 750 | 1400 | 1500 | 2800 | 2800 | 4500 | 4500 |

| Motor (kW) | 435 | 1040 | 1040 | As per your request | |||

| Hydraulic hose (inner diameter) (mm) | 50 | 2×50 | 2×50 | 76 | 76 | 100 | 100 |

Hammer type SC type

Activation

| S-50 | S-75 | S-110 | S-150 | S-200 | |

|---|---|---|---|---|---|

| Maximum impact energy (kNm) | 50 | 75 | 110 | 150 | 200 |

| Minimum impact energy (kNm) | 1 | 3.7 | 6 | 10 | 10 |

Number of blows at maximum blow energy (times/min) |

50 | 50 | 40 | 40 | 40 |

Mass

| S-50 | S-75 | S-110 | S-150 | S-200 | |

|---|---|---|---|---|---|

| Rum (ton) | 3.3 | 5.7 | 7.9 | 11.0 | 13.6 |

| Body (including ram) (ton) | 5.9 | 98 | 14.1 | 18.75 | 26.5 |

Dimensions

| S-50 | S-75 | S-110 | S-150 | S-200 | |

|---|---|---|---|---|---|

| Outer diameter (mm) | 660 | 762 | 1020 | 1020 | 1330 |

| Length (mm) | 5280 | 6115 | 5600 | 6380 | 5660 |

Hydraulic data

| S-50 | S-75 | S-110 | S-150 | S-200 | |

|---|---|---|---|---|---|

| Working pressure (bar) | 220 | 270 | 260 | 280 | 280 |

| Hydraulic oil flow rate (l/min) | 200 | 250 | 460 | 460 | 750 |

| Motor (kW) | 167 | 167 | 344 | 344 | 435 |

| Hydraulic hose (inner diameter) (mm) | 32 | 32 | 38 | 38 | 50 |

Highly Reliable Machine

IHC hydraulic hammer is a highly reliable machine. Safe and easy control.

IHC Hydraulic Hammer Company has developed an electronic control system that is easy to operate and has a wide range of applications.

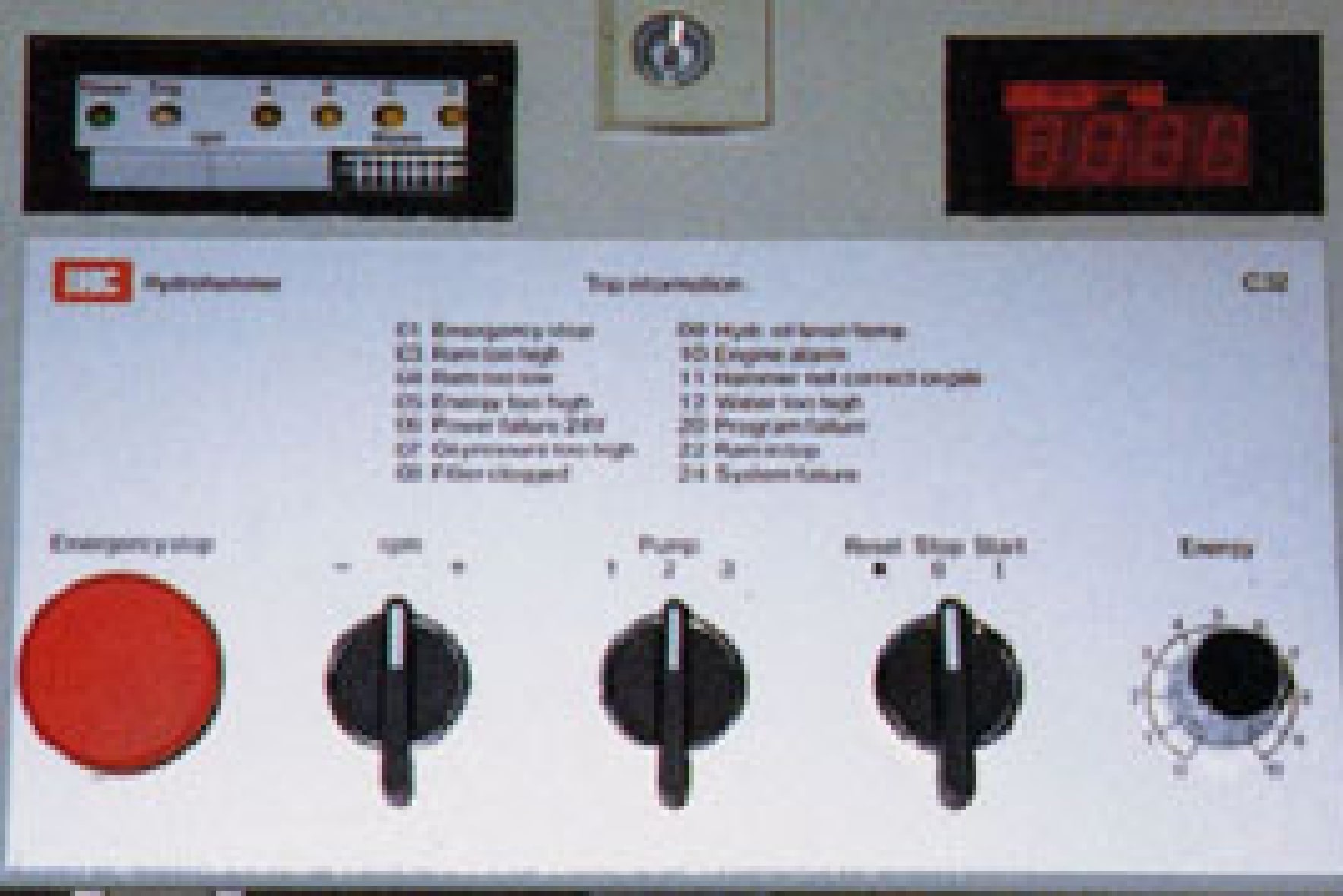

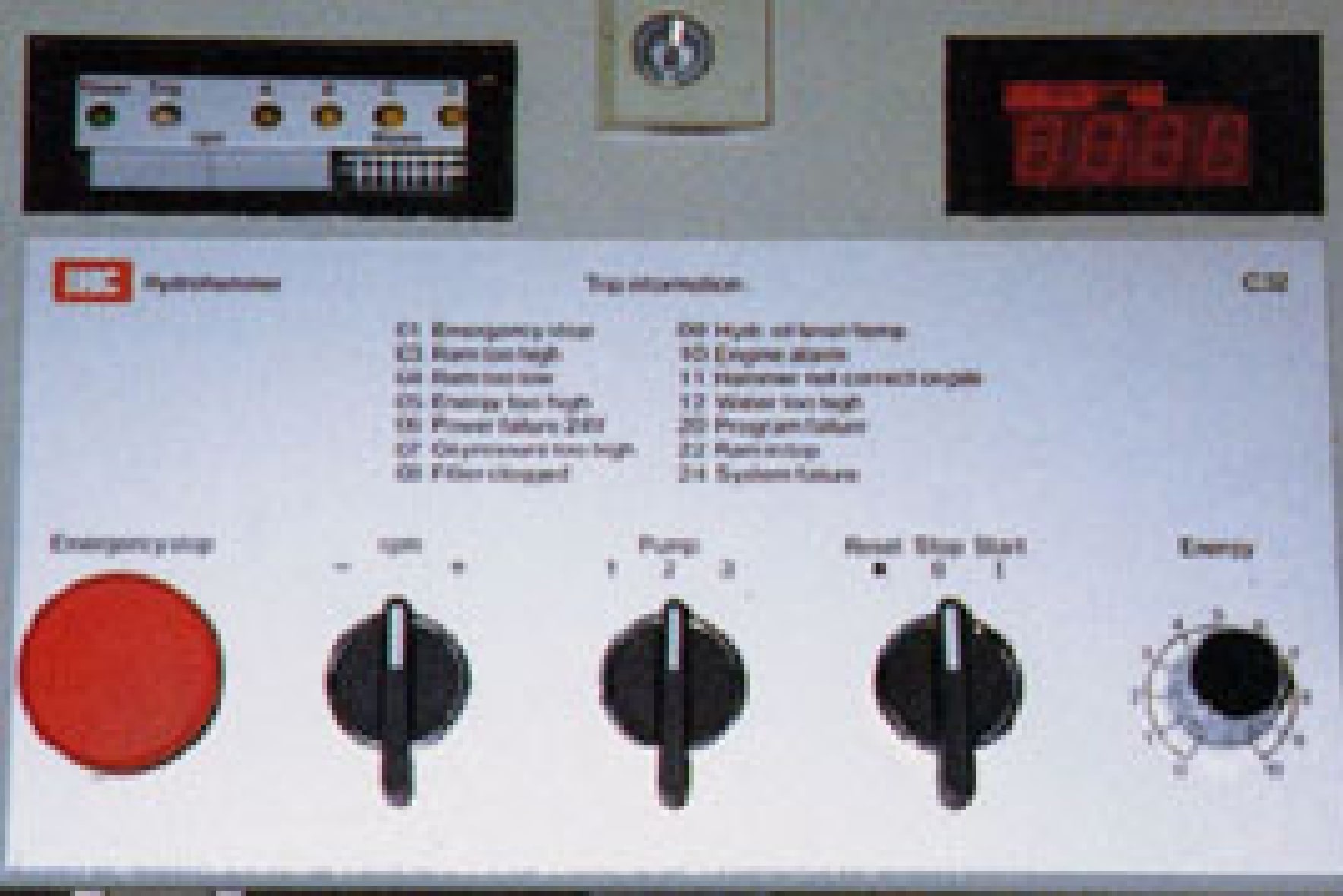

Control unit (C-32)

Japan's first underwater steel pipe pile driving using S-500

- Operations at a glance

- Electronic control system operates pile driving and hydraulics. Important data such as impact energy, number of hits, hydraulic pressure, engine speed and abnormality detection are instantly displayed on the control panel. This ensures safety and the necessary information even when performing underwater pouring.

- Automatic stop function

- The IHC hydraulic hammer will automatically stop when the following operations occur.

- If the pile penetrates faster than the hydraulic hammer.

- If the hydraulic hammer is not set correctly on the pile cap.

- If the impact energy exceeds the set value.

- If the hydraulic hose is not connected correctly.

- When the water level inside the pile sleeve rises abnormally during underwater pouring.

- Automatic pile driving report

- IHC Hydraulic Hammer's pile driving printer can record the following data.

- Construction name

- Pile number

- Date and time

- Pile driving start/end time

- Penetration amount

- Number of blows per 25cm of penetration

- Average impact energy per 25 cm of penetration

- Number of blows per minute

- Total number of hits

- Total impact energy

- Abnormal occurrence

- Multi-functional, powerful hammer

- IHC hydraulic hammers can also be used in a variety of applications such as:

- It has been proven that 100% of the impact energy is exerted even on 25° inclined piles.

- Can also be placed underwater at a depth of 500m or more.

- Free casting in the air or underwater is also possible using a crane.

- Capable of driving large diameter steel pipe piles of any length. (In this case, a cap and pile guide sleeve are required.)

- Piles can also be pulled out. (In this case, use a small hydraulic hammer and extraction set.)

- The hydraulic hammer pulls out the pile in short upward strokes.

- It is also possible to crush rocks in the air or underwater. Hydraulic hammers are safer and more productive than gunpowder hammers, and are equipped with a chisel set at the bottom of the hammer body.

- Soil compaction is also possible.